Gallery/Projects

Automotive Plant

This particular project presented an exciting opportunity for Superior HVAC to collaborate with an automotive manufacturer embarking on a facility expansion. As the manufacturer sought to enhance their operations, they recognized the need for an efficient cooling system to support their manufacturing processes. Opting for a modular design approach, they entrusted Superior HVAC with the realization of their vision.

The project comprised the development of two distinct manufacturing plants, boasting an initial cooling capacity of over 8000 MBH. Additionally, meticulous planning accounted for nearly 4000 MBH of optional future cooling, reflecting our commitment to scalability and forward-thinking design.

Superior HVAC’s involvement encompassed the creation of multiple sets of drawings, each tailored to specific project phases. These drawing sets were issued for design, construction, and fabrication, ensuring a seamless transition from concept to reality. In particular, our fabrication package included all the essential details required for the prefabrication of piping, streamlining the manufacturing process and minimizing on-site installation challenges.

Furthermore, our team supplied comprehensive documentation for the installation of piping and mechanical equipment, leaving no room for ambiguity in execution. Leveraging advanced clash detection software, we took a leadership role in coordinating the efforts of various stakeholders, including structural, architectural, electrical, controls, fire protection, civil, underground plumbing, and on-site mechanical trades.

With years of experience in the industry, Superior HVAC played a pivotal role in ensuring the project’s smooth and efficient progression through the design process. This project exemplifies our commitment to excellence in modular design and our ability to contribute positively to complex, large-scale expansion projects in the automotive manufacturing sector.

Beverage Industry

Our engagement with a client in the beverage industry encompassed a multifaceted mission aimed at enhancing sustainability and efficiency. At the core of this project was the imperative to reduce potable water consumption and minimize wastewater discharge associated with the water treatment equipment and pasteurizers.

This undertaking also challenged us to find innovative and cost-effective solutions for transferring heat to cool the pasteurizers. In addition, we were responsible for conducting comprehensive load calculations to ensure the entire system’s optimal performance.

Furthermore, we were entrusted with producing Process and Instrumentation Diagrams (P&IDs) and 3D modeling. The 3D modeling included space claims for the existing facility and laying out new process piping and equipment, adding another layer of efficiency and functionality to the project.

Our collaboration with the beverage industry client exemplified Superior HVAC’s ability to tackle complex challenges with a keen eye for sustainability and operational excellence. This project underscores our commitment to providing comprehensive solutions that address critical industry needs while delivering measurable benefits.

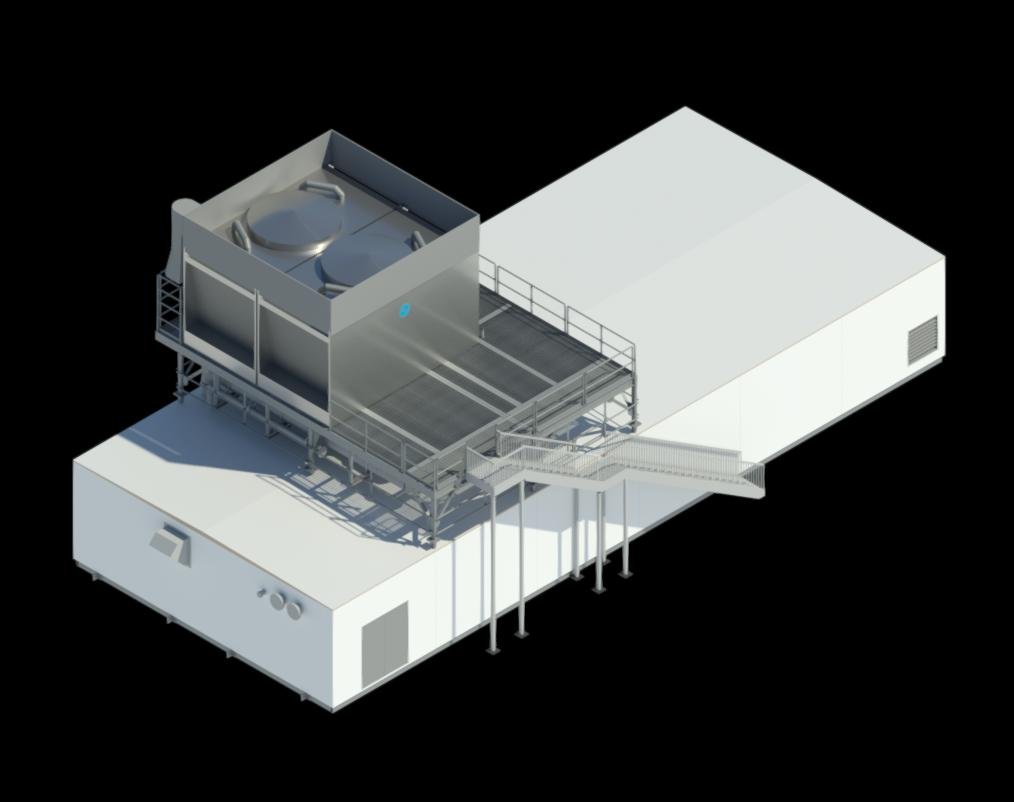

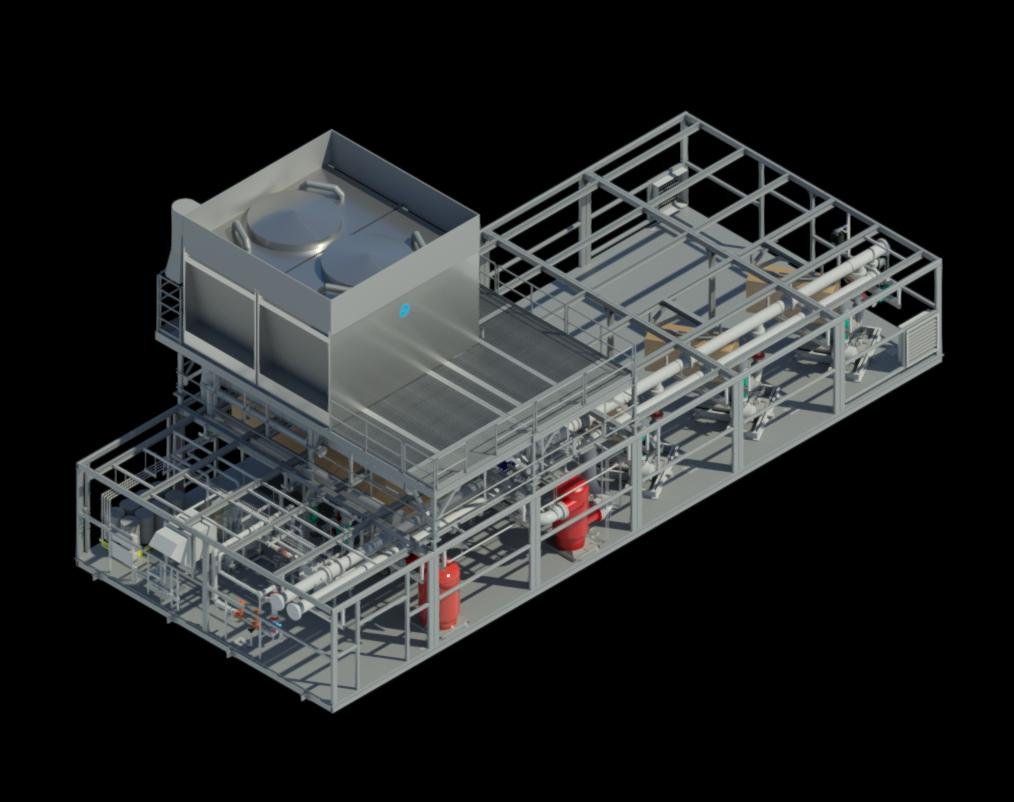

Modular Cooling

This compact modular project served the needs of a discerning food manufacturing company seeking enhanced cooling for their production processes. In alignment with our client’s commitment to environmental responsibility and efficiency, R-717 refrigerant was used for this project.

Superior HVAC’s contribution extended beyond concept to a complete fabrication package, meticulously detailing the piping and equipment. This comprehensive package facilitated efficient and precise fabrication, minimizing errors and ensuring a successful implementation. A rigorous clash detection process was carried out, minimizing rework, and optimizing the manufacturing process.

Notably, this project showcased Superior HVAC’s versatility, as we not only managed the mechanical system but also demonstrated our proficiency in electrical design, an integral part of the fabrication package.

Recognizing the value of this project as a showpiece, the customer requested realistic renderings to showcase its capabilities to potential clients. We gladly obliged, providing visually compelling renderings that further enhanced the project’s appeal as a selling point for future endeavors.

Superior HVAC’s commitment to excellence and innovation is exemplified in this successful modular cooling solution for our esteemed client in the food manufacturing industry.

Air Handler Vestibule Piping

This project catered to the specific needs of a client operating in the air handling sector. Their primary requirement was to obtain accurate pricing for the installation of piping within air handler vestibules, encompassing chilled water, heating hot water, and low-pressure steam systems. Superior HVAC was selected as the trusted partner for this critical project.

Notably, this project demanded a swift turnaround for the deliverables, and we rose to the occasion. Within a mere day of receiving the bid documentation, we provided the client with the comprehensive pricing they needed. Our commitment to accuracy extended to covering all essential aspects, including raw materials, valves, components, and labor for the skilled pipe fitters involved in the project.

By delivering pricing that the client could rely on, we empowered them to present a confident and accurate estimate to their end user. Superior HVAC’s dedication to precision and efficiency shone through in this project, highlighting our ability to meet demanding timelines and deliver results that instill trust in our clients.

Retrofit Project

This industrial project involved a significant undertaking on behalf of a client in the food industry. The project centered around the conversion of their refrigeration system from synthetic R-22 to a more environmentally conscious solution, specifically R-717 ammonia and CO2. Superior HVAC was enlisted to orchestrate this transition by providing a comprehensive package that included permit-ready documentation for submission to local authorities and a set of meticulously crafted construction drawings. These drawings served as the foundation for the on-site contractor during the execution of the project.

A notable challenge we encountered was the absence of existing 3D models for the facility. To overcome this obstacle, we utilized cutting-edge point cloud scans to meticulously capture the building’s layout and utilities. This innovative approach enabled the on-site contractor to install and implement the new equipment and piping with minimal disruptions to the facility’s ongoing production operations during the retrofit.

At Superior HVAC, our expertise extends beyond modular design projects; we are also adept at handling traditional construction and retrofit projects. This successful project exemplifies our commitment to delivering exceptional results, regardless of project scope or complexity.